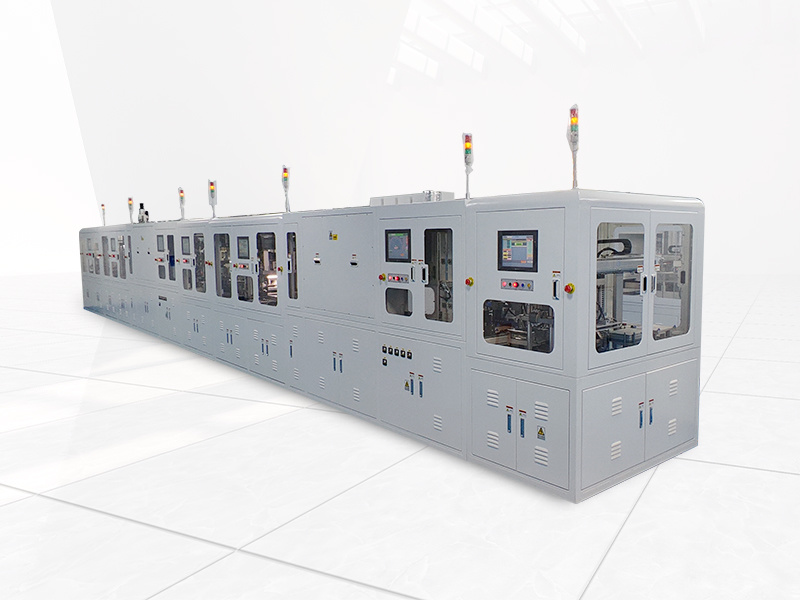

Automatic 310mm Roll to Roll stacking machine【Stacking Process】【For MLCC】

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Category:

Hotline: +8618948669375

WeChat: lixing18948669375

Product Name: Automatic 310mm Roll to Roll stacking machine

Product nickname:Fully Automatic Laminating Machine、Fully Automatic Layer Stacking Machine、Automatic Film Laminating Machine、Roll-to-Roll Laminating Machine、Laminating Machine、Layer Stacking Machine

Model number: LXDC-A02

Machine Dimensions: Details are shown in the table below

Equipment Weight: Details are shown in the table below

Application Products

Our equipment is capable of performing a wide range of electronic component manufacturing processes, including MLCG, MBG, NTC, Filter, Fuse and LTCC.

MLCC

MLCI

NTC

Filter

Fuse

LTCC

- Description

- Region 2

- Region 1

-

- Commodity name: Automatic 310mm Roll to Roll stacking machine【Stacking Process】【For MLCC】

- Product Type: Full-automatic production line

- Consumables Board: Stainless steel end plates

- Product Specification: large size

- Automatic production line accessories: Capacitors

- End Sealer + Drying Oven: Automatic dryer

- End Sealer + Manual Auxiliary: Manual implanter

pecification 310X310mm; Capable of processing film with a thickness of 1.5um-10um and a total of 800 layers.

► Specifications 310X310mm; capable of processing film thickness from 1.5um to 10um, with a total of up to 800 layers.

► Stacking time per layer: 6.0-8.0 seconds, laminating mechanism precision ±10um (including optical assistance system).

► Laminating pressure: 80 tons (MAX), suitable for low adhesion force ceramic films; temperature range of the platform: 27-75 degrees Celsius.

► X-axis and Y-axis optical loop feedback mechanism to ensure full compensation precision. CCD positioning compensation system.

► Added mechanism to eliminate screw clearance, removing minute precision changes.

► High-precision servo motor displacement mechanism designed to improve speed and accuracy.

► Low tension ceramic film transport system, reducing stretching-induced product deformation.

► Ultra-micro hole suction plate; automatic feeding and receiving system.

► Positive pressure design inside the machine, dust particle size of 0.5um can achieve Level 100 or below.

-

Product Name: Automatic 310mm Roll to Roll stacking machine

Product nickname:Fully Automatic Laminating Machine、Fully Automatic Layer Stacking Machine、Automatic Film Laminating Machine、Roll-to-Roll Laminating Machine、Laminating Machine、Layer Stacking Machine

Model number: LXDC-A02

Machine Dimensions: Details are shown in the table below

Equipment Weight: Details are shown in the table below

-

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Key words:

LiXing

Thank You for Your Attention to LiXing!

Send us your needs for your business, we have professional service team to answer you !