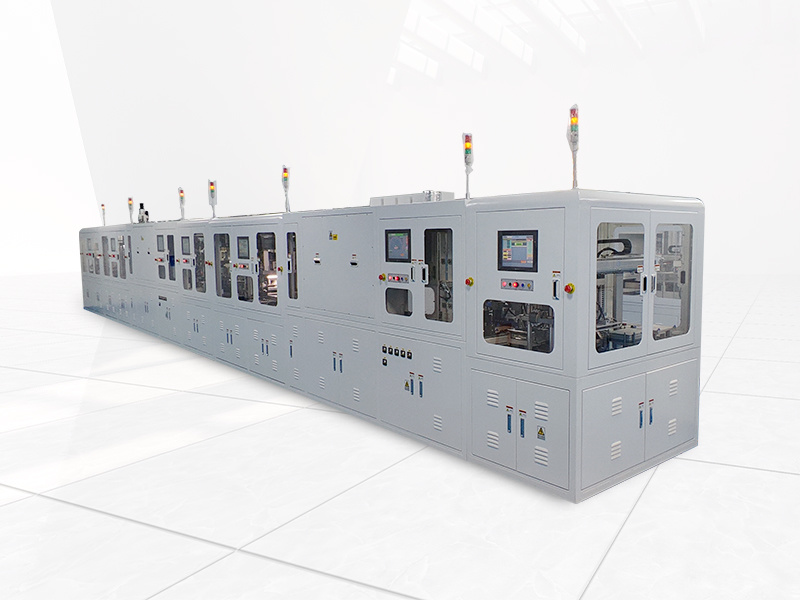

Automatic Dipping Line 【For thick silicone panel】【Dipping machine】【MLCC End-Sealing】

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Category:

Hotline: +8618948669375

WeChat: lixing18948669375

Our fully automatic end-sealing machine consists of the following components: 1. Automatic product implantation → Automatic dipping on the first side → Automatic drying on the first side → Automatic turning of the product → Automatic end-sealing on the second side → Automatic drying on the second side → Automatic unloading of the product (Consists of seven processes)

This automated production line is suitable for a variety of electronic components, including Multilayer Ceramic Capacitors (MLCC), Multilayer Chip Inductors (MLCI), Chip Resistors (CHIP R), Chip Thermistors (CHIP NTC), and Self-Recovering Fuses, among others. It encompasses a range of processes from end sealing and dipping to Surface-Mount Device (SMD) assembly.

Technical specifications:

Applicable pallet size: 240X140mm

Applicable product specifications: 0201-7676

Feeding rate: 97%

Continuous single board efficiency: ≤30S/board

Equipment size: 275014502100

Suction accuracy: ≤±5um

Scraper blade flatness: ≤±5um

Parallelism of paste plate and carrier: ≤±5um

Feeding method: board rack feeding and receiving

The drying oven adopts three-temperature zone hot air circulation "ferris wheel" rotation drying.

Application Products

Our equipment is capable of performing a wide range of electronic component manufacturing processes, including MLCG, MBG, NTC, Filter, Fuse and LTCC.

MLCC

MLCI

NTC

Filter

Fuse

LTCC

- Description

- Region 2

- Region 1

-

- Commodity name: Automatic Dipping Line 【For thick silicone panel】【Dipping machine】【MLCC End-Sealing】

- Product Type: Full-automatic production line

- Consumables Board: Stainless steel end plates

- Product Specification: large size

- Automatic production line accessories: Capacitors

- End Sealer + Drying Oven: Automatic dryer

- End Sealer + Manual Auxiliary: Manual implanter

Suitable for MLCC、Resistor、Inductor、Fuse and more。Sealing Process,Dipping Process,SMD Process

Product name

Fully automatic sealing line for thick silicone panel

Suitable for carrier plate specifications

240mm x 140mm Stainless Steel Plate

Applicable product specifications

Imperial 0805-1812

Product feeding rate

97%

Efficiency of continuous single plate mode

≤30 seconds per plate

This device automatically implants products into the guide plate through vibration, and accurately presses the products inside the guide plate into the holes of the thick rubber plate through a press.

Before sealing, the product is uniformly leveled by a servo leveling mechanism to ensure that the protruding length of each chip is consistent, and the consistency of the product sealing end is good.

The face changing machine adopts a plate changing method for product end conversion, which reduces the phenomenon of end scraping caused by face changing and also improves the service life of the pressure needle.

Equipped with automatic slurry addition and numerical control of slurry height, with slurry laying line detection and alarm function during slurry laying

Pressure bed, leveling platform, end sealing platform, and surface changing unloading platform are equipped with detection sensors at each corner to prevent residual product breakage needles on the board surface and affect the quality of product end sealing

The drying oven adopts a five temperature zone hot air circulation "Ferris wheel" rotation method for drying, which has the characteristics of large capacity, uniform heating, fast drying, and high temperature control accuracy.

The entire line is equipped with a return frame and return mechanism. After unloading, thick rubber plates can be returned to the implantation machine through the return frame, and impurities on the plate surface can be cleaned without the need for manual plate removal. -

Our fully automatic end-sealing machine consists of the following components: 1. Automatic product implantation → Automatic dipping on the first side → Automatic drying on the first side → Automatic turning of the product → Automatic end-sealing on the second side → Automatic drying on the second side → Automatic unloading of the product (Consists of seven processes)

This automated production line is suitable for a variety of electronic components, including Multilayer Ceramic Capacitors (MLCC), Multilayer Chip Inductors (MLCI), Chip Resistors (CHIP R), Chip Thermistors (CHIP NTC), and Self-Recovering Fuses, among others. It encompasses a range of processes from end sealing and dipping to Surface-Mount Device (SMD) assembly.

Technical specifications:

Applicable pallet size: 240X140mm

Applicable product specifications: 0201-7676

Feeding rate: 97%

Continuous single board efficiency: ≤30S/board

Equipment size: 275014502100

Suction accuracy: ≤±5um

Scraper blade flatness: ≤±5um

Parallelism of paste plate and carrier: ≤±5um

Feeding method: board rack feeding and receiving

The drying oven adopts three-temperature zone hot air circulation "ferris wheel" rotation drying.

-

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Key words:

LiXing

Thank You for Your Attention to LiXing!

Send us your needs for your business, we have professional service team to answer you !