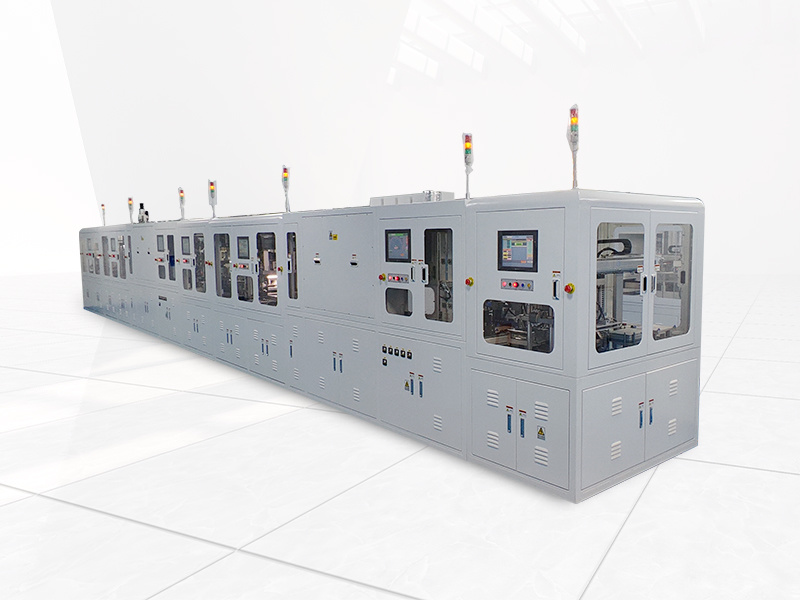

Automatic Dipping Line - 01005 Stainless Steel End Sealing Plate【Dipping machine】【MLCC End-Sealing】

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Category:

Hotline: +8618948669375

WeChat: lixing18948669375

Our fully automatic end-sealing machine consists of the following components: 1. Automatic product implantation → Automatic dipping on the first side → Automatic drying on the first side → Automatic turning of the product → Automatic end-sealing on the second side → Automatic drying on the second side → Automatic unloading of the product (Consists of seven processes)

This automated production line is suitable for a variety of electronic components, including Multilayer Ceramic Capacitors (MLCC), Multilayer Chip Inductors (MLCI), Chip Resistors (CHIP R), Chip Thermistors (CHIP NTC), and Self-Recovering Fuses, among others. It encompasses a range of processes from end sealing and dipping to Surface-Mount Device (SMD) assembly.

Product Name: Automatic End Sealing Line - 01005 Stainless Steel End Sealing Plate

Product nickname:Automatic Dipping Machine Line - 01005 Stainless Steel End Sealing Plate、Automatic End Silvering Machine Line - 01005 Stainless Steel End Sealing Plate、Automatic Coating Machine Line - 01005 Stainless Steel End Sealing Plate

Model number: LX02D

Machine Dimensions: Details are shown in the table below

Equipment Weight: Details are shown in the table below

Applicable Specifications:01005-0201

Pallet & Supplies:Stainless Steel series

Application Products

Our equipment is capable of performing a wide range of electronic component manufacturing processes, including MLCG, MBG, NTC, Filter, Fuse and LTCC.

MLCC

MLCI

NTC

Filter

Fuse

LTCC

- Description

- Region 2

- Region 1

-

- Commodity name: Automatic Dipping Line - 01005 Stainless Steel End Sealing Plate【Dipping machine】【MLCC End-Sealing】

- Product Type: Full-automatic production line

- Consumables Board: Stainless steel end plates

- Product Specification: large size

- Automatic production line accessories: Capacitors

- End Sealer + Drying Oven: Automatic dryer

- End Sealer + Manual Auxiliary: Manual implanter

Suitable for MLCC、Resistor、Inductor、Fuse and more。Sealing Process,Dipping Process,SMD Process This automatic line: Automatic product insertion → Automatic end-sealing of the first side → Automatic drying of the first side → Automatic flipping → Automatic end-sealing of the second side → Automatic drying of the second side → Automatic product unloading (7 machines connected) Customizable to meet current customer needs through modular modifications

Product name

Fully Automatic End Sealing Line-- 01005 Stainless Steel End Sealing Plate

Suitable for carrier plate specifications

240mm x 140mm Stainless Steel Plate

Applicable product specifications

Imperial 01005-0201

Product feeding rate

98%

Efficiency of continuous single plate mode

≤30 seconds per plate

Hole count for 01005 and 0201 products: The 01005 product has 50,338 holes per plate, while the 0201 product has 55,360 holes per plate.

Automatic features: Equipped with automatic adhesive application and automatic product implantation with an implantation rate of over 98%. Before leveling post-implantation, there's an automatic cleaning function for the upper and lower surfaces of the plate and a waiting area for detection of products that are misaligned on the plate surface.

Slurry application and control: Features automatic slurry application and digital control of slurry height, with an alarm function for detecting errors in slurry spreading and line drawing (detection accuracy of 0.1mm), and a flatness precision of the slurry tray of ≤±0.004mm.

Scraper and parallelism requirements: The flatness of the scraper blade must be ≤±0.004mm, it must be wear-resistant and rust-free; the relative parallelism between the slurry tray and the carrier platform must be ≤±0.004mm.

Product precision and end sealing accuracy: For the imperial 01005, the accuracy is (84±15um), and for 0201, it is (90±20um).

Drying oven features: The drying oven uses a three-temperature zone hot air circulation with a "Ferris wheel" rotation drying method, which features large capacity, uniform heating, quick drying, and high-precision temperature control.

Remote control and diagnostics: The entire machine can be remotely controlled, with the capability to detect equipment faults and address issues promptly, improving maintenance and production efficiency.

-

Our fully automatic end-sealing machine consists of the following components: 1. Automatic product implantation → Automatic dipping on the first side → Automatic drying on the first side → Automatic turning of the product → Automatic end-sealing on the second side → Automatic drying on the second side → Automatic unloading of the product (Consists of seven processes)

This automated production line is suitable for a variety of electronic components, including Multilayer Ceramic Capacitors (MLCC), Multilayer Chip Inductors (MLCI), Chip Resistors (CHIP R), Chip Thermistors (CHIP NTC), and Self-Recovering Fuses, among others. It encompasses a range of processes from end sealing and dipping to Surface-Mount Device (SMD) assembly.

Product Name: Automatic End Sealing Line - 01005 Stainless Steel End Sealing Plate

Product nickname:Automatic Dipping Machine Line - 01005 Stainless Steel End Sealing Plate、Automatic End Silvering Machine Line - 01005 Stainless Steel End Sealing Plate、Automatic Coating Machine Line - 01005 Stainless Steel End Sealing Plate

Model number: LX02D

Machine Dimensions: Details are shown in the table below

Equipment Weight: Details are shown in the table below

Applicable Specifications:01005-0201

Pallet & Supplies:Stainless Steel series

-

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Key words:

LiXing

Thank You for Your Attention to LiXing!

Send us your needs for your business, we have professional service team to answer you !