Automatic Drying Oven【For MLCC】

Suitable for MLCC、Resistor、Inductor、Fuse and more。 Sealing Process,Dipping Process,SMD Process

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Category:

Hotline: +8618948669375

WeChat: lixing18948669375

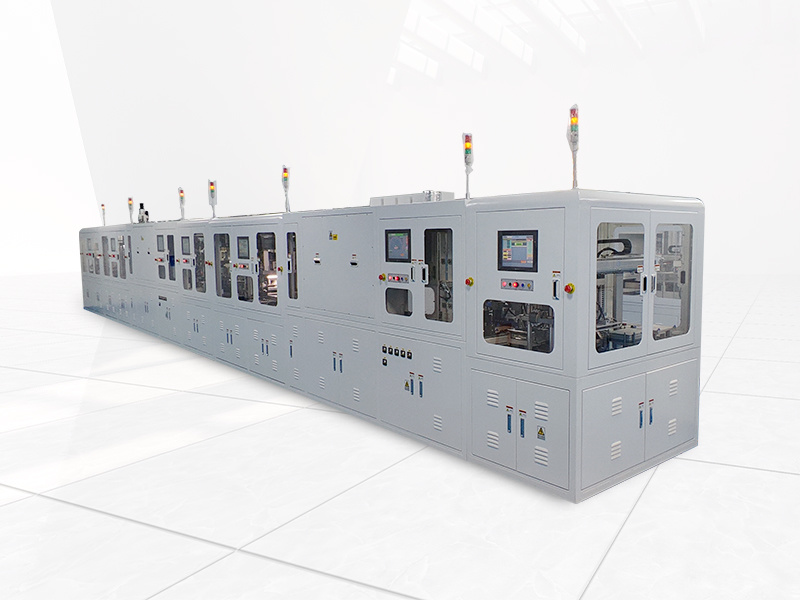

Product Name: Automatic Drying Oven

Product nickname:Drying Oven、Mesh Belt Furnace Dryer

Model number: LXHG(Mesh Belt Furnace Dryer)、LXHG(Ferris wheel drying oven)

Machine Dimensions: Details are shown in the table below

Equipment Weight: Details are shown in the table below

Applicable Specifications:Contact your account manager for details

Pallet & Supplies: (SUS)Stainless Steel series 、Thick Silicone series 、Thin Silicone series 、(JIG)Fiberglass plate series

Application Products

Our equipment is capable of performing a wide range of electronic component manufacturing processes, including MLCG, MBG, NTC, Filter, Fuse and LTCC.

MLCC

MLCI

NTC

Filter

Fuse

LTCC

- Description

- Region 2

- Region 1

-

- Commodity name: Automatic Drying Oven【For MLCC】

- Product Type: Full-automatic production line

- Consumables Board: Stainless steel end plates

- Product Specification: large size

- Automatic production line accessories: Capacitors

- End Sealer + Drying Oven: Automatic dryer

- End Sealer + Manual Auxiliary: Manual implanter

Contact your account manager for details

Three-zone hot air circulation "Ferris wheel" rotation drying: The machine uses a three-temperature zone hot air circulation method with a Ferris wheel rotation style for drying. This design offers advantages such as large capacity, uniform heating, fast drying, and high temperature control precision.

Adjustable board movement time: The time for moving each board can be set between 15 seconds and 60 seconds, allowing for customization based on the specific drying requirements.

Maximum temperature of 150°C: The machine can reach a maximum temperature of 150°C, suitable for various drying processes that require high temperatures.

High-temperature monitoring and protection for heating elements: The machine is equipped with a monitoring and protection system for the heating elements to prevent overheating and ensure safe operation.

-

Product Name: Automatic Drying Oven

Product nickname:Drying Oven、Mesh Belt Furnace Dryer

Model number: LXHG(Mesh Belt Furnace Dryer)、LXHG(Ferris wheel drying oven)

Machine Dimensions: Details are shown in the table below

Equipment Weight: Details are shown in the table below

Applicable Specifications:Contact your account manager for details

Pallet & Supplies: (SUS)Stainless Steel series 、Thick Silicone series 、Thin Silicone series 、(JIG)Fiberglass plate series

-

Suitable for MLCC、Resistor、Inductor、Fuse and more。 Sealing Process,Dipping Process,SMD Process

Due to the small differences in different specifications, the detailed data of the equipment can be consulted by email to our account manager

Key words:

LiXing

Thank You for Your Attention to LiXing!

Send us your needs for your business, we have professional service team to answer you !